3/4 Day Basic Level

This course is aimed at trainee setters that have limited experience and are aiming at NVQ 2 or equivalent.

- Polymers and applications used in Extrusion Blow Moulding such as HDPE, PP, PET (G) and PVC.

- Exploring what pre production checks should be carried out.

- Material handling and preperation

- Dealing with regrind

- Checking heating and temperature control readings

- Starting the machine logically and safely

- Adjusting: /die gap/screw speed

- Head Tooling: Die/Core/Core Receiver. Die & Core cleaning

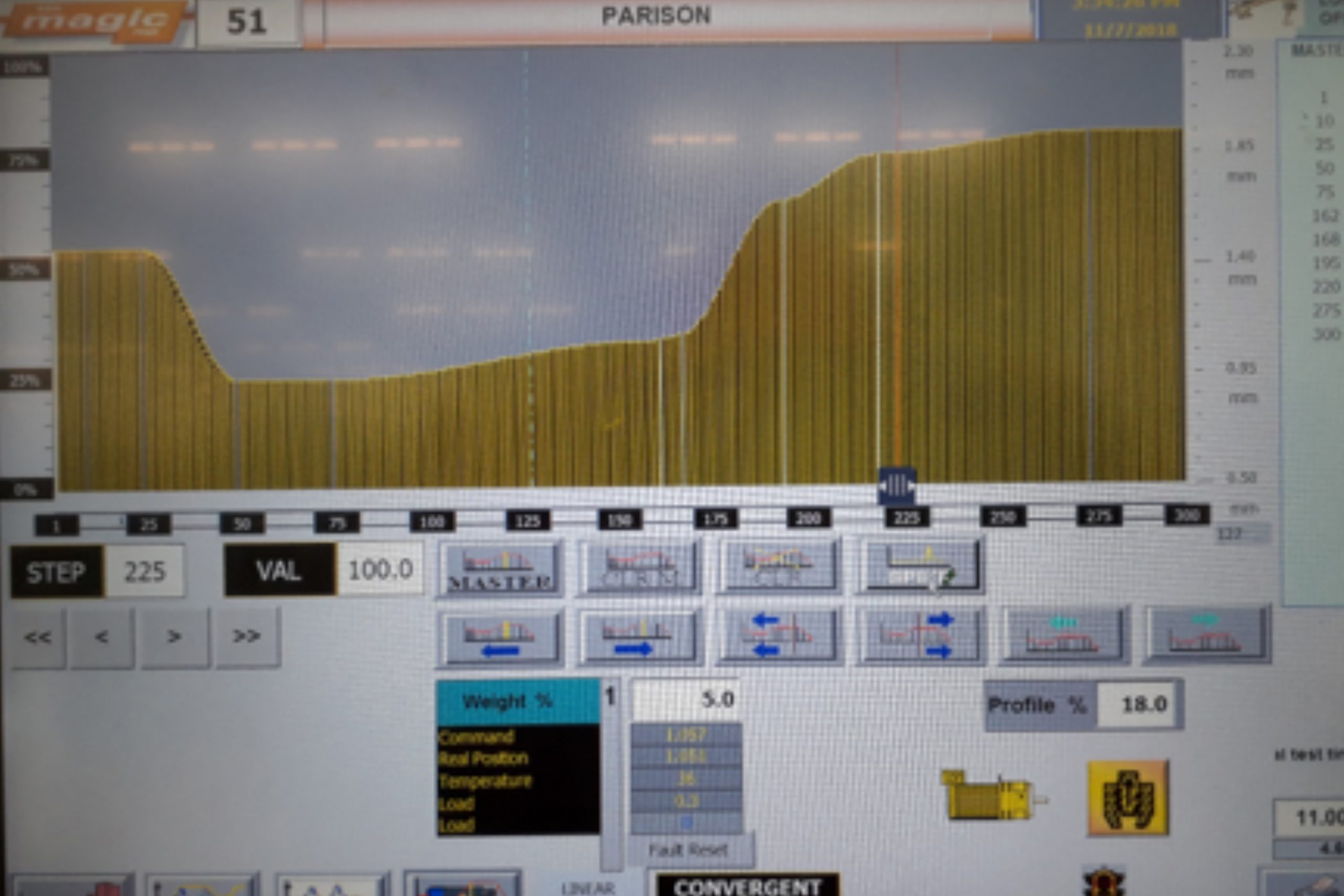

- Basic Parison Programming: Function or components and minor adjustment of profile

- Parison Faults: Drag lines, Poor Distribution and Sagging

- Monitoring and recording production data

- Moulds: Care and basic maintenance

5 Day Intermediate / Advanced Level

This course is aimed at experienced setters/technicians who are aiming at NVQ 3 or equivalent.

The course content will cover:

- Polymer and applications used in Extrusion Blow Moulding such as HDPE, PP, PET (G) and PVC

- Exploring what pre production material tests are practical such as MFI and discussing how the viscosity of the material is affected by the regrind

- Typical material problems such as moisture, contamination and melt fracture

- Extruders: Heating and temperature control

- Grooved fed/smooth barrel. Output and L/D ratio

- Head Design: Accumulator & Continuous

- Shot volume/die gap/screw speed

- Head Tooling: Die/Core/Core Receiver. Die & Core designs

- Ovalised tooling, converge/diverge

- Parison Programming: Function of components, Set up, Minimum Gap Setting, Relationship between positional points, profile range and basic weight. Radial wallthickness control, application and limitations.

- Parison Faults: Drag lines, Poor Distribution and Sagging

- Blowing ration and Die Swell

- Moulds: Design basics, Choice of Materials, Cooling, Pinch off design, venting and cooling temperature and pressures

- Blowing: Pressures of Pre Blow and Main Blow

- Process sequence: What happens & when

- Production faults: Holes, contamination, Shrinkage, Distortion, poor distribution, weak weld

- Commercial implications of cycle time and weight optimisation

2 Day Advanced

This would be aimed at very experienced technicians who had prior knowledge of the 5 day course content.

It would concentrate on trouble shooting and be comprised of three sections:

- Product fault analysis

- Logic methodology…short/long term variables

- Process fault analysis