Extrusion Blow Moulding Courses

All of the listed courses can be held in company, or by utilising equipment at Wolverhampton College,

Telford, UK.

Generic commercial topics such as Material Yield, Understanding costs of materials, moulds and equipment plus the implications of cycle time and over weight product are covered.

Project Consultancy

Independent advice misgiven on new designs, manufacturability, machinery and vendor selection plus budgetary costings.

Help is given to answer:

Can this design be made commercially?

Which technology is appropriate?

What volume do I need to have my own mould made?

Who could make such a mould?

Who can make the components?

How much investment is required?

Management & Buyers Training

Do you know what you are buying?

Is your supplier giving you credible answers on costs and quality? Do you understand the key cost drivers and their impact on cost?

A one or two day programme is offered, that is aimed at Management and Buyers of Rigid Plastics.

Topics covered as follows:

Basic technology understanding of Injection Moulding

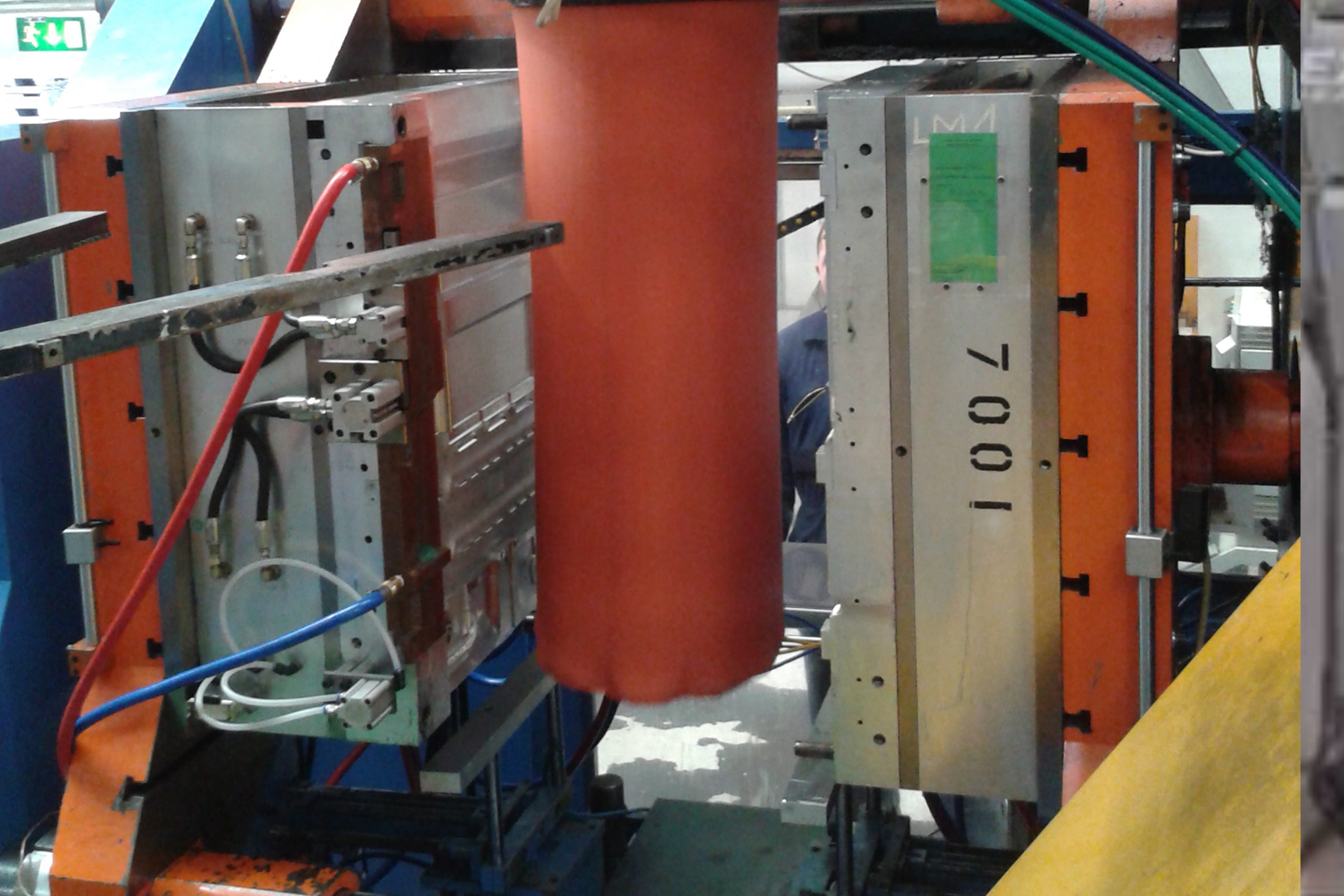

Extrusion Blow Moulding

Injection Blow Moulding and Injection Stretch Blow Moulding

(As these are modules, please select as appropriate).

Identify and examine the key cost drivers e.g. cycle time, cavitation, utilisation, machinery capital, polymer cost as a percentage of total cost and other conversion costs.

This programme can be run either in company or at Wolverhampton College, Telford, UK where production equipment is utilised to demonstrate the technology and fuse commercial and technical aspects of Rigid Plastics.

Packaging Training

Do you really understand the packs you are designing, developing or buying? This technical programme is offered to Packaging Developers, Designers and Buyers. It can cover the following modules and is typically conducted over 3-5 days at Wolverhampton College, Telford, UK.

Modules: Plastics materials: Polymerisation, Thermoset v Thermoplastic, Crystalline and Amorphous resins, Melt flow index and density. Implications of using regrind. Material selection, applications and limitations.

Basic Level Product and Mould Design: Predictive analysis, functionality, selecting a polymer, Mould manufacture and component functions, mould types: 2 plate, 3 plate, Semi and full hot runner.

Primary Technologies: Injection Moulding, Extrusion Blow Moulding, Injection Blow Moulding (Theory only), Injection Stretch Blow Moulding (Theory only).

Applications/Limitations of each technology, cost of moulds/dies and lines, outputs, capital costs, typical volumes required to gain entry to the chosen technology, typical quality issues, job changeovers, colour changes.

The strength of this course is the opportunity to have hands on experience.

Automotive Training

Automotive Training for applications such as bumpers, fuel tanks, washer bottles, filler pipes and trim.

Modules: Plastics materials: Polymerisation, Thermoset v Thermoplastic, Crystalline and Amorphous resins, Melt flow index and density. Implications of using regrind. Material selection, applications and limitations.

Basic Level Product and Mould Design: Predictive analysis, functionality, selecting a polymer, Mould manufacture and component functions, mould types 2 plate, 3 plate, Semi and full hot runner.

Primary Technologies such as Injection Moulding and Extrusion Blow Moulding will be covered in detail.

Applications/Limitations of each technology, cost of moulds/dies and lines, outputs, capital costs, typical volumes required to gain entry to the chosen technology, typical quality issues, job changeovers, colour changes.

These courses can be held: On site where the equipment/application i.e. multi layer fuel tanks is very specific.

At Wolverhampton College where Injection and Blow Moulding equipment is available for hands on training.

Auditing and Supplier Improvement

Is your mouldmaker/moulder up to standard? How do you know? If you are a mouldmaker/moulder, how do you rate against your competition?

Over the last 15 years BIA has audited over 100 mouldmakers and more than 300 moulders covering every Continent. This service is offered to End User companies looking to place mould orders or component supply contracts. It is also used by mouldmakers and moulders for self assessment against an International criteria.

Mouldmaker audit: Housekeeping, CAD capability and control, Incoming steel checks, material selection, Hardness verification, Part to part interchangeability, flow of work, QA, Project management, Lead time control, Customer interface, mould and component qualification, moulder training/technical support and after sales, shot guarantees, dispatch procedure and commissioning at the moulder.

Moulder audit: Housekeeping, In coming material checks, Material storage, handling and blending, Yield calculation and control, Utilities (compressed air, cooling water), Primary and Ancillary machinery (general condition), cycle times, machine set up, general safety, machine technician understanding, SOP (standard operating procedures) mould changeover equipment, mould maintenance equipment, mould storage/history/records etc. QA systems and equipment.Packing, storage and dispatch of components.

Distance Learning

This is available in course slide format and includes:

a) A PowerPoint slide pack showing the Blow Moulding Process, machine components and function, processing and trouble shooting.

b) Email support regarding any questions.

c) Telephone sessions referencing the slides and your specific project.

Quality Training

Keep getting disputes between QA and Production? Do your QA people know the main Extrusion Blow Moulding faults? Do they know the impact of rejecting or accepting batches according to the fault?

This one day programme is held on site at your factory and can cover the following:

Fault recognition: Contamination, Holes, Ovality, Rough neck seal, Wings (Ears), Panelling, Shrinkage and deformation, Bubbles (Fish Eyes), Die Lines (Drag lines, Burn lines), Sharkskin (Melt fracture), Orange peel, Rocking bases etc plus any company specific issues.

Automotive and Packaging applications can be accommodated and the relevant faults selected accordingly.